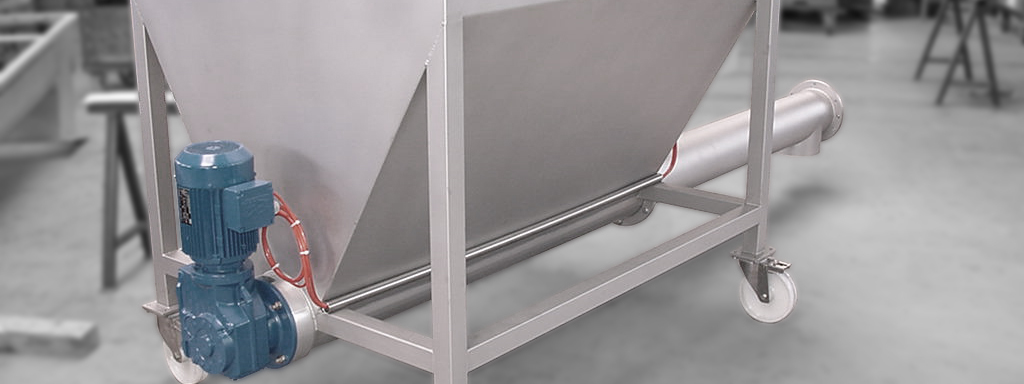

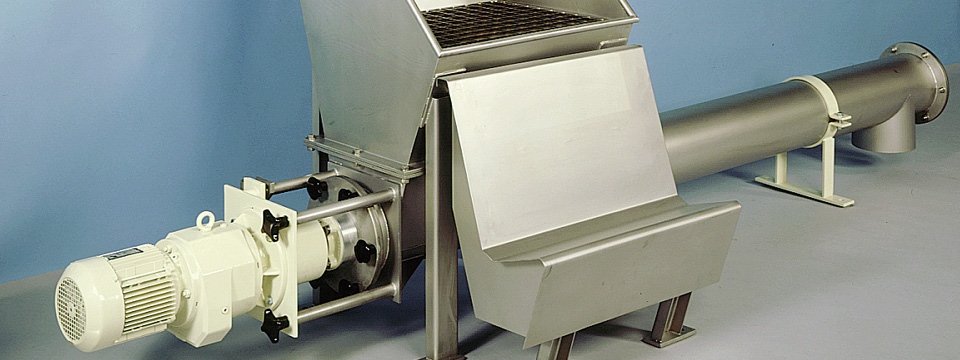

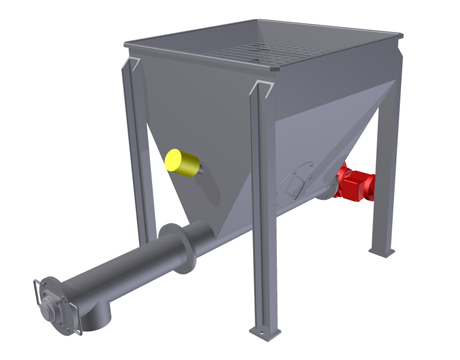

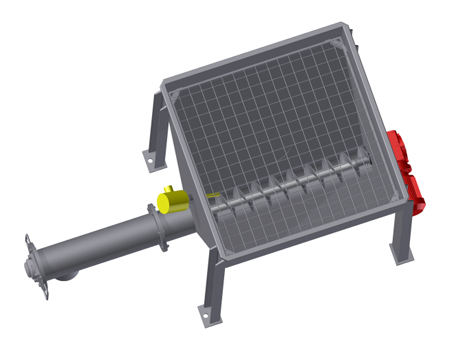

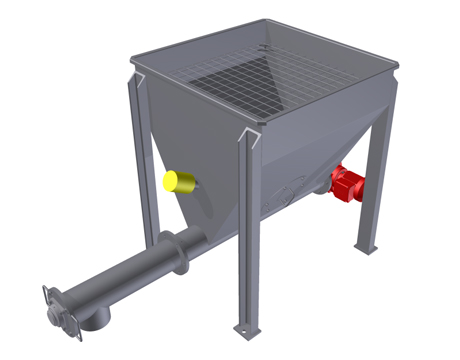

Dosing hopper

Function:

Dosing hoppers serve as a reception facility of the product and control the flow rate of the production line by supplying a constantly dosed flow.

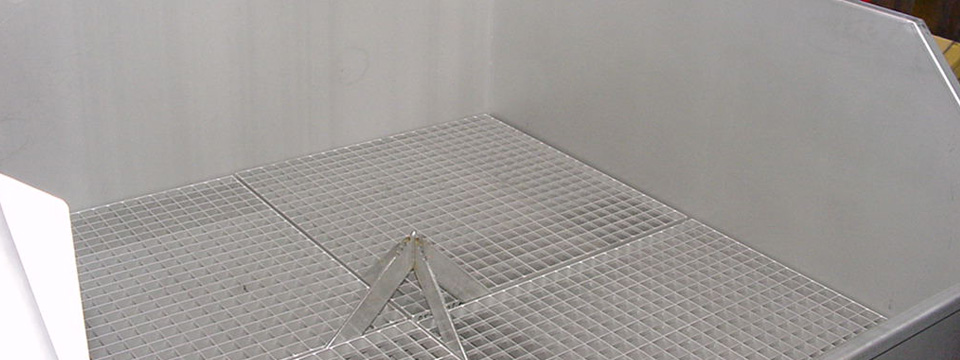

The product flows from the hopper into the dosing spiral and is carefully transported by it to the outlet. The spiral geometry enables the exact volumetric dosage. The speed can be regulated through a frequency-controlled drive motor. The hopper’s holding capacity can be adjusted according to your requirements. We usually use 500L, 1000L, and 2000L.

Advantages:

- volumetric dosage

- customized solutions